Manufactured Under Strict Hygenic Conditions

Our state of the art production facility with class 20000 sq. meter area, controlled with air handling units(AHU) having 0.3 micron Hepa filters to maintain temperatures below 30 degree centigrade room temperature.

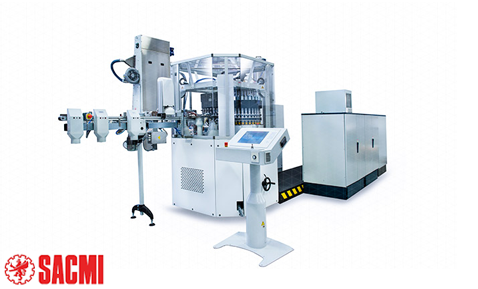

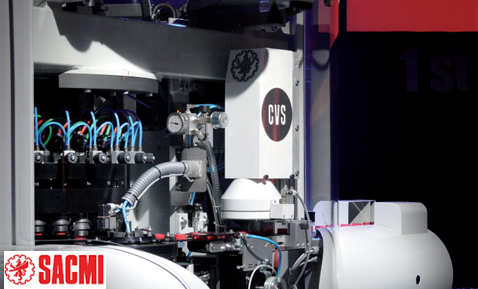

We also have Hi tech fully automated plant with high speed (up to 1200 caps /min) SACMI compression molding machines for manufacturing caps and closures with 100 % on line 3 CVS auto inspection systems installed to avoid any type of rejections in caps specially used for packing of 100ml to 3000ml carbonated beverage products.

Our Production capacity is more than 40 million closures per month.

Our State of Art Process

01

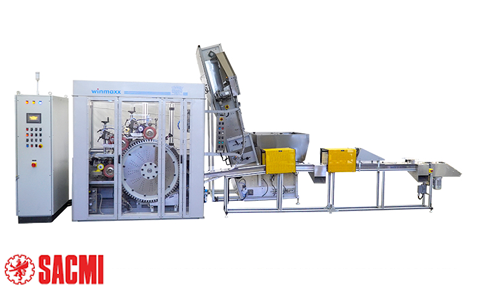

CCM - Compression molding cap

02

SFM - Slitting and folding of closures

03

PMV - In Shell lining of two piece closures

04

CVS Auto Inspection Systems

05

Automatic Cap Printing Machine